It is a metalworking tool. It consists of a massive block of metal. The metal usually is cast steel; you may know some details about it, but do you learn about the history of the anvil, use of it, how to make an anvil? When you use this tool, you can see a tight top surface. You can use this fastened top surface to stuck another object upon this.

The inertia and the energy both are proportional to each other. The power of the unique tools depends on the inertia.

How much the inertia increases, the energy also increases. It usually is a primary tool for metalworkers. The surface of the device is critical.

You need it fastened obviously as the total energy transfers to the workpiece. You may know some details about it, but do you learn about the history of the anvil, use of it, how to make an anvil?

If you don’t know, we have prepared for you this.

History of anvil:

You may know about the anvils very well. But do you know where we can find these most? Do you know the history of the anvils? If you don’t know, we have prepared this for you. Let’s have a look.

In the ancient era, people made anvils with stone at first. They used the stone as a lithic stone tool. After that, they used Bronze to make anvils and wrought iron after that.

Steel is available easily. That’s why they started to use steel to make the anvils. And gradually, steel became the face of it. People used steel so that anvils could get a hard surface.

They used steel also to stop the anvil from deforming from impact. Smith used the first-ever version of anvils. But the anvil changed its form and turned into different shapes.

It became more advanced day-by-day. People used a variety of types of styles in the anvil and changed its form. They are always used to update the anvils.

The majority of the anvil is available today in the country US. In the 19th century, they used the London pattern anvils.

When people learned the use of wrought iron in the anvil, they continued this through the 19th and the beginning of the 20th century. They kept the wrought iron, the face of the anvil, till the beginning of the 20th century.

They used different types of processes to make anvils in the desired shape. But it depended upon the other anvil makers how they would keep sequence and locate the forge-welds.

It also depended upon the type of the anvil they are going to create. The United States was making cast iron anvils with steel faces at that time.

At the end of the 20th century, people produced solid cast steel anvils. But people use today modern anvils made from pure steel.

You can get plenty of references in ancient Greek and Egyptian writings. People have found it at the Calico Early Man Site in North America.

Structure of an anvil

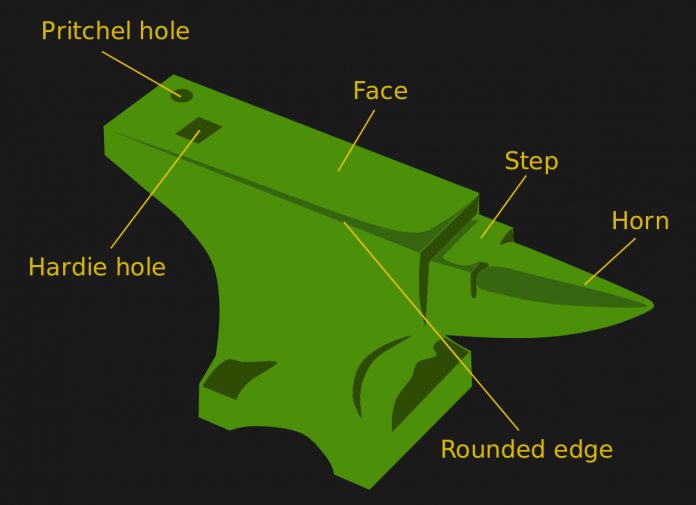

An anvil is a metalworking tool. Pritchel hole, Rounded edge, Face, Step, Horn, Hardie hole are the parts of the anvil.

It is flat and smooth. People generally use hardened steel to make this anvil.

Pritchel Hole:

It is a small round hole. We can see this Pritchel Hole present on most of the modern anvils.

People use it for punching. It has an extra hole. Smith used it to get more flexibility.

Rounded Edge:

Sometimes few marks seem to remain in the round edges. It may harm the workpiece. It may cause cracks to it.

Face:

People made the face of the anvil very hardened, smooth, and tempered. It is because of the pressure of the Hammer.

We made this strong so that it doesn’t deform after a long time of use.

Step:

People use it for cutting. It is the area between the horn and the face.

Horn:

People use this part to form different types of round shapes. If you want to make it longer and thinner, you can use it. You can use it for bending also. There are one square horn and one round horn in some anvils.

Hardie Hole:

When you want to place some cutting tools into it, you should use this part of the anvil. It is a square hole used for punching and bending operations.

Features Of An Anvil:

- Durable

- Impact surface for working parts

- Made from large source material like stone or metal

- Supports chiseling, hammering, and forging

- Use heat-treated cast or forged steel.

- Use Hardie Hole for bending operations.

How to place an anvil:

You need to place the very safely. It needs a sturdy base when you are going to place it. The base must contain an impact and fire-resistant material.

We normally use a large Wood Log or large timber. It is very heavy. That’s why you need to bury these into some depth of the soil so that it sticks the soil tightly.

At first, you need to fix the, and then you should use it. Must bind them tightly with the base so that it cannot move while using. A loose anvil causes an accident.

If you don’t fasten it tightly, the tool may fall from the base. Then it may become an ineffective one, which will be of no use.

There are some easy and regular methods to attach an anvil. The processes are spikes, chains, steel or iron straps, clips, bolts. A smith used to use whatever he got near him.

You need to place the anvil near the forge. It is convenient. Sometimes more than one step can lose your heat in the workpiece.

The user should always use such types of materials, which make the anvil heavier. You must be immobile the anvil so that it doesn’t move a lot. In this case, Cast iron is the one that everyone prefers to use.

It is easily available in industrial areas. People once used stone, and now they use pure steel. You can use a large block or a thick container with full Sand so that the base becomes strong.

Types of anvil:

You can go through the huge range of anvils that are obtainable at Woodward Fab. These are acceptable for different types of applications. People use these different types of anvils differently.

These have various types of dimensions. The weights of the anvil models are different also. Let’s have a look at these amazing models of anvils.

Anvil Model A11 – this model is a small anvil. The weight of this anvil is 11 pounds. The dimensions of this anvil are 10″ x 3″ x 4″.

Anvil Model A22 – The dimension of this type of anvil is 14″ x 4″ x 4″. The weight of the A22 model anvil is approx 22 pounds.

Anvil Model A66 – model 66 of the anvil has around 66 pounds weight. This model has the dimensions of 22″ x 5″ x 7″.

Anvil Model A154 – The anvil model A154 weighs about 154 pounds. It has a Rockwell hardness of 45-55. The dimensions of this type of anvil are 28″ x 6″ x 9″.

Anvil Model A220 –

The awesome tensile strength of 87000 psi makes this anvil stronger and durable.

Now according to the application area and the use, we can divide the anvils into four categories. We can get different types of shapes- small, medium, and large. The anvils are-

- Sheet Metal Anvils

- Forging Anvils

- Shoeing Anvils

- Bench Anvils

We can also differentiate a lot of anvils like:

- Forging Anvils: It has a weight of about 75 pounds to 500 pounds. We know it as blacksmiths.

- Cast-iron Anvils: We know it as ASO or “Anvil shaped object.” These are very low-quality anvils. It generally breaks after use.

- Farrier Anvils: It has high quality. The range from the weight is 100 to 150 pounds. People use cast steel or hardened iron to make this type of anvils.

- Stake Anvils: The weight of the anvil is around 15 to 20 pounds.

- Bench Anvils: 5-50 pounds is the weight of the anvils.

- Jewelers Anvils: It has a wide range from a few ounces to a few pounds.

Use of anvil:

There are plenty of different uses of anvils, such as:

Block Loot:

When you want to assign some anvils, there is always a risk of breaking. It drops itself at the time of breaking with the current tools. Chipped anvil and dropped anvil use to drop themselves.

Breaking:

People mine these anvils using any type of pickaxe. But it doesn’t drop anything if people mine this without a pickaxe.

Repairing and renaming items:

You can combine two similar items with the anvils. You can also use materials to combine the items and turn them into a single one. One material can help to repair about 25% of the maximum durability.

As an example, if you combine 2 Diamonds shovels, it costs only 2 Diamonds to make. But to repair one with individual diamonds would take four diamonds.

Repair:

An anvil can repair iron pickaxe with the help of iron. The iron ingots help to repair the chain armor. You can use the Scutes to repair the Turtle Shells.

Damage:

It has a low quality of damage percentage, which is about 12%. That’s why the percentage of damage is quite low, and people love to use the anvils. It is preferable to all the users.

People also use it as an instrument as it makes a huge noise.

How to make an anvil :

- At first, you need to open your crafting table so that you can get the 3×3 crafting grid table.

- After that, your second job is mainly to add the items into it to make the anvil. People use the 3×3 crafting grid. We use this to make the crafting area.

When you want to make an, you have to place three iron blocks and four iron ingots. You must place this in the crafting grid. When you make an, you should look after the exact position of the iron blocks and the iron ingots.

- In the first row, you should place three blocks of iron and one iron ingot in the second row. You have to place the iron ingot in the middlebox.

- You should keep the first and third boxes empty. In the third row, there should present three iron ingots. You can say that it is the Minecraft crafting recipe for any type of anvil.

- In the crafting grid, you can make the design as you like. The anvil will appear right to it.

Quality of a good anvil:

The anvil should be hard, powerful, unyielding, steady. Steel is a magnificent component. An excellent anvil’s main material should be good-quality steel.

It means this anvil can stand against a hammer smash without caving. It means that an anvil made of cast-iron can get coated in the Hammer formed dens.

Are ancient anvils expensive?

In recent days, inexpensive anvils are very poor in quality as these anvils are made of low-quality material. For this reason, these types of anvils become fragile.

On the other hand, in ancient eras, people used to make anvils with high-quality materials. That’s why ancient is more expensive.

Can you break an?

Good quality can last for a maximum of 24 uses. Because of falling, an anvil can be demolished or perished.

How many times can you use an?

For every use, and gets a 12% chance of damage. You can use 25 times.

What is the perfect cost of an?

If you are looking for an according to your budget, then don’t worry. You can get it. You can get it in $3 to $5 for every pound. A good quality new anvil costs a little more. You can get such anvils in $7 to $ 9 for each pound.

Conclusion:

Today you will get to see that the users use cast or forged steel in most of the anvils so that it gets strong. You should not use low quality steel. Pure steel always makes the tool heavier and reduces the percentage of risk. It keeps the tool safe. We hope, our latest information helps you to know all the information about anvils and gives you an idea about how to make an anvil.